- Understanding the Role of Durable Metalwork in Industrial Settings

- Key Materials and Their Suitability for Different Industrial Applications

- Advanced Techniques in Metal Fabrication for Enhanced Durability

- Case Studies: Successful Implementations of Resilient Metal Structures in Industry

Understanding the Role of Durable Metalwork in Industrial Settings

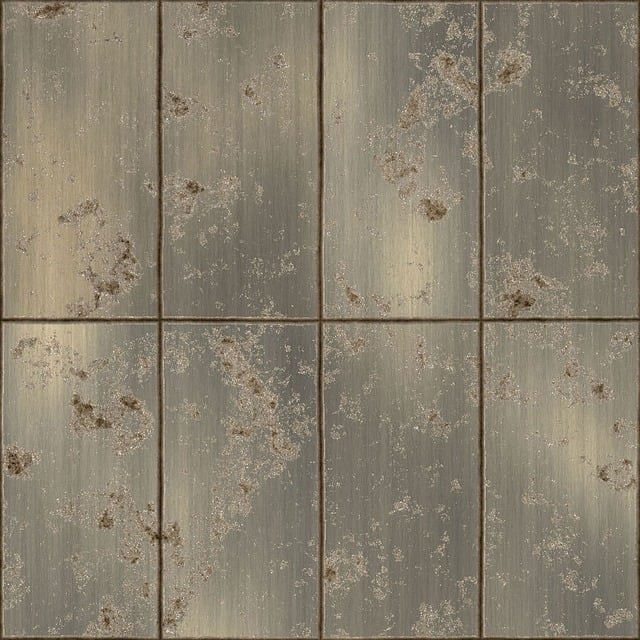

In industrial settings, durable metalwork serves as the backbone of infrastructure, ensuring operational efficiency and safety. These structures are engineered to withstand harsh conditions and intensive use, which is critical for maintaining productivity in environments such as manufacturing plants, mining operations, and construction sites. The choice of materials like stainless steel or high-grade aluminum reflects a commitment to quality and longevity, mitigating the need for frequent repairs or replacements. This resilience not only reduces downtime but also contributes to cost savings over time. The design and implementation of such metalwork must account for factors like load bearing, environmental exposure, and human-machine interaction to guarantee a safe and functional work environment.

The integration of advanced metallurgy techniques in the fabrication of durable metalwork tailored for industrial use offers numerous benefits. These include increased tensile strength, corrosion resistance, and impact endurance. Such enhancements are essential for components that are subject to high stress or extreme temperatures, ensuring they perform reliably under all conditions. Additionally, the sustainability aspect of using durable metals cannot be overstated; it often involves recycling and reusing materials, which aligns with modern industry’s commitment to environmental stewardship. This commitment to both performance and conservation underscores the critical role that metalwork plays in the industrial sector’s continued evolution towards greater efficiency and sustainability.

Key Materials and Their Suitability for Different Industrial Applications

Advanced Techniques in Metal Fabrication for Enhanced Durability

Case Studies: Successful Implementations of Resilient Metal Structures in Industry