Metal fabrication CAD drafting is a vital tool for creating precise sheet metal frameworks, enhancing structural integrity, and optimizing production efficiency. Professionals use advanced software to translate blueprints into detailed 2D/3D models, minimizing errors and facilitating communication. This process involves stress analysis, material selection, and protective coatings to ensure longevity against environmental factors. By simulating fabrication methods like cutting, rolling, or stamping, designers can efficiently plan and reduce waste, marking a significant advancement in modern sheet metal framework construction.

“Unleash the potential of sheet metal in construction with our comprehensive guide. Discover the art of designing robust frameworks and support structures using advanced metal fabrication techniques. From mastering basic framework concepts to leveraging CAD drafting for precision, this article illuminates every step.

Explore design considerations ensuring structural integrity while optimizing metal fabrication processes. Uncover the secrets to creating efficient, durable, and precise sheet metal components, revolutionizing your building projects.”

Understanding Sheet Metal Framework Basics

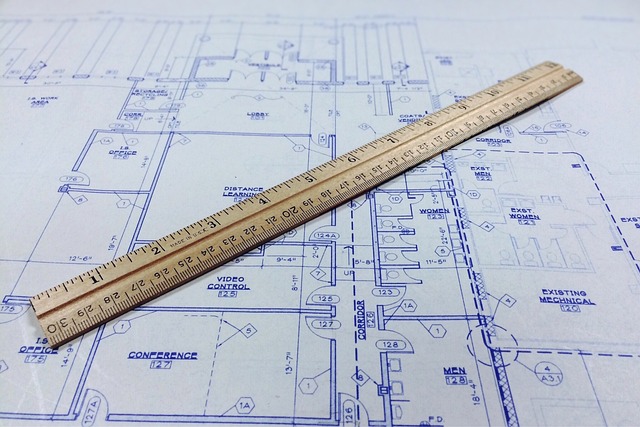

Understanding the fundamentals of sheet metal framework is paramount in metal fabrication. This type of framework, often utilized in construction and industrial projects, involves meticulously designed and cut sheets of metal that are then assembled to create robust structures. CAD drafting plays a pivotal role here, enabling precise measurements and complex designs that ensure structural integrity and aesthetic appeal.

Sheet metal professionals use advanced software to translate architectural blueprints into detailed 2D or 3D models, facilitating the creation of custom frameworks tailored to specific project needs. This digital approach streamlines the design process, improves accuracy, and allows for modifications well before physical production begins. By combining skilled drafting with innovative fabrication techniques, modern sheet metal workers can craft intricate support structures that serve as the backbone of various applications, from buildings and machinery to automotive components.

CAD Drafting for Precision and Accuracy

In the realm of metal fabrication, precision and accuracy are paramount. CAD (Computer-Aided Design) drafting plays a pivotal role in achieving these crucial aspects. By leveraging advanced software tools, fabricators can meticulously design sheet metal frameworks and support structures with microscopic detail. This digital process ensures every dimension, angle, and curve is exact, minimizing errors often associated with manual drafting.

CAD drafting allows for the creation of comprehensive 3D models, offering a holistic view of the final product. This visual representation facilitates better communication among stakeholders, from designers to engineers and manufacturers. Moreover, it streamlines the production process by providing detailed cutting and folding instructions, enhancing efficiency and productivity on the shop floor.

Design Considerations for Robust Support Structures

When designing a sheet metal framework and support structure, several key considerations come into play to ensure robustness and functionality. Metal fabrication specialists often start with detailed CAD drafting to create precise models that factor in load bearing requirements, material properties, and environmental conditions. This digital design process allows for thorough analysis of stress points and structural integrity before production begins, minimizing the risk of failure under various loads.

Additionally, designers must consider factors like corrosion resistance, especially in environments exposed to moisture or chemicals. Choosing suitable metals and applying protective coatings can extend the lifespan of the support structure significantly. Proper spacing between components is also crucial for efficient drainage of condensate and prevention of rust buildup. These thoughtful design considerations ensure that the final sheet metal framework not only supports its intended load but also stands the test of time in diverse operational settings.

Optimizing Metal Fabrication Techniques

In the realm of sheet metal framework and support structure design, optimizing metal fabrication techniques is paramount for achieving structural integrity while minimizing material wastage and production time. Advanced technologies like Computer-Aided Design (CAD) drafting play a pivotal role in this process. CAD software allows engineers to meticulously plan and simulate metal components before production, ensuring precise measurements, reduced human error, and improved overall efficiency.

By leveraging CAD drafting, designers can explore various fabrication methods, such as laser cutting, rolling, or stamping, and select the most suitable approach based on material properties, part complexity, and cost constraints. This not only streamlines the manufacturing process but also enhances the final product’s quality, making it a game-changer for modern sheet metal framework construction.

In conclusion, mastering sheet metal framework and support structure detailing involves a blend of foundational knowledge, advanced CAD drafting techniques, strategic design considerations, and optimized metal fabrication methods. By combining these elements, professionals can create robust, precise, and efficient structures that cater to diverse industrial needs. Leveraging metal fabrication CAD drafting ensures not only accuracy but also streamlines production processes, making it an indispensable tool in modern manufacturing.