Reverse engineering and scan-to-CAD conversion techniques address the challenge of preserving intricate sheet metal and fabrication detailing in legacy parts, where scarce documentation hampers reproduction. These methods enable digital recreation of historical components, ensuring design integrity while allowing modifications, improvements, and contemporary manufacturing adherence to safety standards. Advanced scanning technologies capture detailed geometry, tolerances, and material properties, enhancing productivity, precision, and innovation in modernizing sheet metal and fabrication components.

In today’s digital age, legacy parts pose a unique challenge for manufacturers. “Reverse engineering and scan-to-CAD conversion” offer innovative solutions for revitalizing these outdated components. This article explores the intricate process of bringing historical designs into the modern era, focusing on sheet metal fabrication detailing. We delve into understanding legacy parts’ historical context, the challenges they present, and how reverse engineering empowers us to recreate digital blueprints accurately. Get ready to discover how this technology revolutionizes manufacturing for vintage designs.

Understanding Legacy Parts: A Historical Perspective

Legacy parts, often complex creations of sheet metal and fabrication detailing, are a testament to human ingenuity and historical craftsmanship. These parts, dating back decades or even centuries, were designed and manufactured before the advent of modern Computer-Aided Design (CAD) software. Their creation relied heavily on skilled artisans, precise measurements, and intricate manual labor. With time, these legacy components have become critical to various industries, from aviation and automotive to machinery and infrastructure.

Preserving and understanding these historical parts is a delicate process, especially as the original blueprints and documentation may be scarce or outdated. Reverse engineering, combined with scan-to-CAD conversion techniques, offers a powerful solution. By meticulously studying the physical parts, engineers can recreate their digital twins, enabling modifications, improvements, and even reproduction while maintaining the integrity of the original design aesthetics.

Challenges in Sheet Metal Fabrication for Old Designs

Legacy parts, often with intricate designs and complex geometry, pose unique challenges when it comes to sheet metal fabrication. These older designs might lack detailed digital blueprints or specifications, making the process of creating accurate replicas or replacements difficult. Without access to original engineering plans, fabricators must rely on reverse engineering techniques to decipher the design nuances and create precise sheet metal components.

The intricacies involved in these old designs often include intricate folds, creases, and flanges that demand meticulous attention during fabrication. Manual interpretation of such detailing can be time-consuming and prone to human error. Moreover, material properties and manufacturing constraints of the past may differ from modern standards, requiring fabricators to adapt their techniques to achieve the desired results while adhering to contemporary safety and quality guidelines.

Reverse Engineering: Unlocking Digital Blueprints

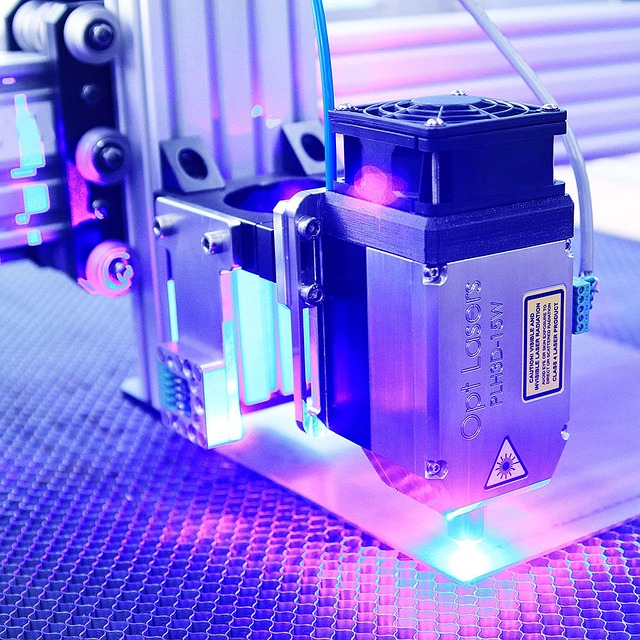

Reverse engineering is a powerful process that brings legacy parts into the digital age, offering a fresh perspective on their design and manufacture. By employing advanced scanning technologies, engineers can capture intricate details of sheet metal and fabrication components, creating precise 3D models. This technique is particularly valuable for older or hard-to-obtain items, where traditional blueprints might be outdated or incomplete.

Through reverse engineering, digital blueprints are unlocked, providing an accurate representation of the part’s geometry, tolerances, and material properties. These virtual models become the foundation for further analysis, design modifications, or even the creation of new CAD (Computer-Aided Design) files. With access to detailed sheet metal and fabrication data, manufacturers can enhance productivity, improve precision, and explore innovative ways to optimize legacy components for modern production processes.

Scan-to-CAD Conversion: Modernizing Legacy Components

Scan-to-CAD conversion offers a modern solution for legacy components, particularly in sheet metal and fabrication detailing. By utilizing advanced scanning technologies, this process accurately captures the geometry and dimensions of older parts that may lack digital representations. The scanned data is then converted into CAD (Computer-Aided Design) formats, enabling engineers and manufacturers to work with up-to-date digital models.

This approach streamlines the design and manufacturing processes, improving efficiency and reducing potential errors associated with manual tracing or reverse engineering from physical prototypes. With detailed sheet metal and fabrication drawings easily accessible in digital form, teams can collaborate more effectively, making modifications and updates faster while ensuring precision and consistency across various stages of production.

Legacy parts, with their intricate designs often rooted in historical manufacturing practices, pose unique challenges for modern sheet metal fabrication. However, through reverse engineering and scan-to-CAD conversion technologies, these old components can be revitalized. By accurately recreating digital blueprints from physical parts or existing CAD files, manufacturers can streamline the production process, enhance design flexibility, and ensure precision in sheet metal fabrication. This innovative approach bridges the gap between traditional craftsmanship and modern manufacturing, allowing for the preservation and evolution of legacy parts while catering to contemporary demands.