Steel structure modeling requires creating precise 3D models using specialized software to represent material properties, load calculations, and component connectivity. Accurate data collection through manual entry and advanced scanning technologies ensures detailed digital twins. Validation, testing, and refinement ensure model integrity, identify weaknesses, and optimize structural performance. Choosing the right software with advanced geometric modeling, material property application, and comprehensive suites streamlines the design process for complex steel structures.

In today’s construction industry, precise steel structure modeling is paramount for project success. This article delves into the intricacies of detailed steel and concrete structure modeling, highlighting critical aspects like understanding modeling needs, selecting appropriate software, and data collection methods. We explore validation techniques, testing procedures, and refinement strategies to ensure accuracy in design. By mastering these steps, professionals can achieve robust steel structure models, fostering efficiency and safety across projects.

Understanding Steel Structure Modeling Needs

Understanding the intricacies of steel structure modeling is paramount in ensuring accurate and efficient construction projects. Steel structures, given their complexity and intricate design elements, demand precise modeling to meet structural integrity and aesthetic requirements. This process involves meticulous digital representation, allowing engineers and architects to visualize and analyze the entire framework before physical construction begins.

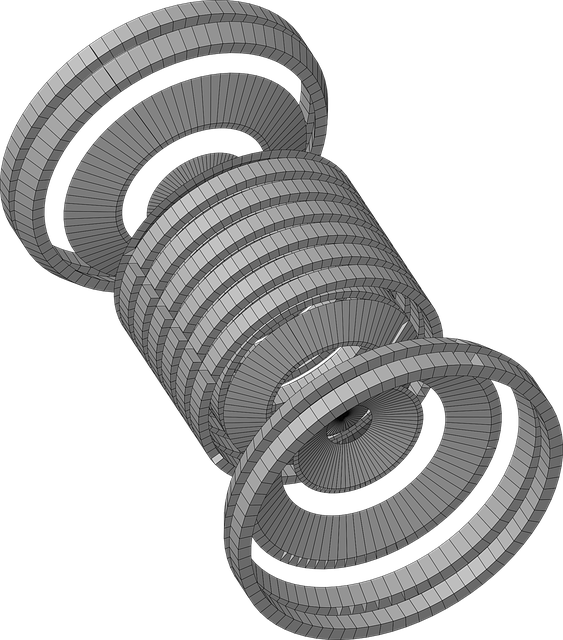

Effective steel structure modeling necessitates addressing key considerations such as material properties, load calculations, connectivity between components, and dimensional accuracy. By employing specialized software and tools, professionals can create detailed 3D models that replicate the structural behavior of steel elements under various conditions. This enables thorough testing, identification of potential issues, and optimization of designs for both functionality and visual appeal.

Choosing Suitable Software and Tools

Choosing the right software and tools is a pivotal step in achieving accurate steel structure modeling. The market offers various options, each with unique features catering to different project complexities and user preferences. For intricate steel structures, specialized structural engineering software designed for advanced analysis and design is essential. These programs provide engineers with the capability to model complex geometric shapes, apply material properties, and perform detailed load calculations, ensuring structural integrity.

When selecting tools, consider factors like ease of use, compatibility with industry standards, and the ability to integrate with other software used in the project lifecycle. Popular choices include industry-standard platforms that offer comprehensive suites for steel structure modeling, detailing, and documentation. These tools often come with preloaded libraries of standard components, saving time and effort during the design phase.

Accurate Data Collection and Input Methods

Accurate data collection is paramount in steel structure modeling, as it forms the foundation for achieving precise and reliable results. High-quality input methods are essential to ensure every detail of the structural design is captured correctly. This includes meticulous measurements, utilizing advanced scanning technologies like LiDAR or 3D laser scanning to capture intricate geometry and dimensions. These techniques enable engineers to digitize existing structures with remarkable accuracy, providing a comprehensive digital twin for future reference.

Additionally, data input should incorporate both manual entry and automated processes. While manual data collection ensures quality control, automating certain tasks through software integration streamlines the modeling process. This approach, combining human expertise with digital efficiency, is crucial in managing complex steel structures, ensuring every component, joint, and connection is accurately represented, leading to improved structural analysis and design integrity.

Validation, Testing, and Refinement Techniques

Validation, testing, and refinement are essential steps in ensuring the accuracy of steel structure modeling. To begin with, validation involves comparing the digital model against physical measurements and established industry standards to confirm its integrity and correctness. This can be achieved through detailed comparisons of dimensional data, load capacity calculations, and material properties, ensuring that the model accurately represents the intended real-world structure.

Testing plays a crucial role in identifying any discrepancies or potential failures within the design. Engineers conduct simulations to expose the model’s weaknesses, subjecting it to various loads, environmental conditions, and stress scenarios. By refining the model based on test results, designers can optimize structural performance, enhance safety margins, and ensure the structural integrity of steel components. This iterative process of validation and testing is vital for achieving high-quality, error-free steel structure modeling.

Accurate steel structure modeling is paramount in construction for safety, cost-effectiveness, and project success. By understanding specific needs, selecting appropriate software, collecting and inputting data meticulously, and employing validation techniques, engineers can achieve precise models that enhance design integrity. Leveraging these practices ensures robust steel structure modeling, fostering informed decision-making throughout the entire construction process.