Prototyping in sheet metal and fabrication detailing is vital for pre-production, testing design functionality, aesthetics, and structural integrity through iterative modeling. 3D visualization streamlines this process, enabling early detection of design flaws, material optimization, and aesthetic refinement. Advanced manufacturing techniques like CAD, CNC, and 3D printing create precise models, facilitating thorough testing and ensuring final products meet high-quality standards. This data-driven approach saves time, costs, and resources while enhancing product robustness, safety, and reliability in sheet metal and fabrication detailing.

“In the realm of pre-production, prototyping and 3D visualization are game-changers for designers and manufacturers. This article explores how these powerful tools transform creative concepts into tangible realities, especially in the context of sheet metal fabrication detailing. We delve into the benefits of 3D visualization for enhancing precision and efficiency, and navigate the iterative process crucial for refining designs before final production. By understanding prototyping’s role and leveraging 3D tech, professionals can streamline their workflow, ensuring flawless results.”

Understanding Prototyping in Pre-Production

Prototyping is a critical step in the pre-production phase for many manufacturing processes, especially those involving intricate designs like sheet metal and fabrication detailing. It involves creating a physical model or replica of a planned product to test its functionality, aesthetics, and structural integrity before mass production. This iterative process allows designers and engineers to identify and rectify flaws or make improvements, ensuring the final product meets high-quality standards.

In the context of sheet metal fabrication, prototyping enables thorough inspection of components such as panels, frames, and enclosures. By subjecting these parts to stress tests, impact assessments, and endurance trials, manufacturers can predict performance in real-world scenarios. This proactive approach to quality control not only saves time and costs associated with fixing issues at later stages but also enhances the overall design, making it more robust, safe, and reliable.

Benefits of 3D Visualization for Sheet Metal

In the realm of sheet metal and fabrication, 3D visualization offers unparalleled advantages for pre-production testing. It allows engineers and designers to catch intricate design flaws or inefficiencies early on, streamlining the production process significantly. By creating a digital twin of the final product, stakeholders can thoroughly inspect every detail, from bend angles and paneling to fastening points. This level of precision ensures that the physical prototype aligns perfectly with the intended design, minimizing costly rework later.

Moreover, 3D visualization empowers teams to explore various material options, finishes, and surface treatments virtually. This capability is instrumental in enhancing aesthetic appeal and ensuring structural integrity simultaneously. By visualizing fabrication detailing in three dimensions, companies can make informed decisions regarding material usage, waste reduction, and overall product quality, setting the stage for a more efficient and successful manufacturing journey.

Fabrication Detailing: Bringing Designs to Life

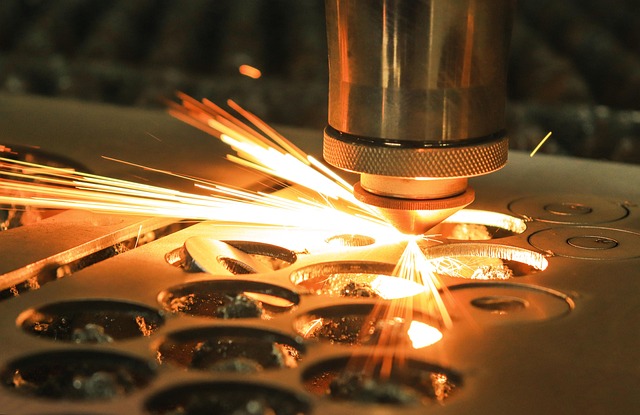

In the realm of prototyping and 3D visualization, sheet metal and fabrication detailing play a pivotal role in transforming digital designs into tangible realities. This meticulous process involves crafting precise models that accurately represent the final product, allowing for comprehensive pre-production testing. Skilled artisans employ advanced techniques to create intricate sheet metal components, ensuring every detail aligns with the initial concept.

From computer-aided design (CAD) software to CNC machining and 3D printing, modern fabrication technologies enable engineers and designers to bring their visions to life with exceptional accuracy and speed. These detailed prototypes facilitate rigorous testing, enabling teams to identify potential issues early in the development cycle. By subjecting these models to real-world conditions, manufacturers can ensure the final product will meet performance standards, offering a seamless transition from design to production.

Testing and Iteration: Refining Your Concept

Testing and iteration are vital components of prototyping, allowing designers and engineers to refine their concepts through practical application. Each prototype provides valuable insights, highlighting areas that need improvement or adjustments in design, functionality, and structural integrity—especially when it comes to intricate sheet metal and fabrication detailing.

By simulating real-world conditions, 3D visualization enables the identification of potential issues early in the development cycle. This iterative process ensures that the final product meets or exceeds expectations, saving time and resources. Through continuous testing and refining, creators can transform initial ideas into robust designs, ready for mass production, while seamlessly integrating any required sheet metal and fabrication details.

Prototyping and 3D visualization are powerful tools that streamline pre-production testing, especially in sheet metal and fabrication detailing. By utilizing these methods, designers can efficiently refine concepts, identify issues early on, and make informed decisions before full-scale production. This iterative process not only saves time and resources but also ensures the final product meets high-quality standards, turning creative visions into tangible realities.