Industrial steel structure drafting is key to creating seismically resistant buildings. By leveraging steel's strength and ductility, drafters design flexible yet robust frames that can absorb energy during earthquakes. Advanced connectors, reinforced with plates and bolts, enhance structural integrity. Precise detailing, specific fastening methods, and compliance with building codes ensure safety in industrial environments. Collaboration between specialists and meticulous planning are vital for constructing structures capable of resisting seismic events.

In the realm of seismic-resistant construction, steel connection detailing plays a pivotal role in ensuring structural integrity. This article delves into the critical aspects of designing with industrial steel structures, focusing on optimizing connector strength and seamless integration. By understanding the unique properties of steel and adhering to best practices for safe assembly, architects and engineers can create robust, earthquake-resilient buildings. From drafting connectors for optimal performance to implementing effective structural assembly techniques, each step is essential in navigating the intricate landscape of seismic design.

Understanding Steel's Role in Seismic Design

Steel plays a pivotal role in seismic-resistant construction, offering engineers and architects a powerful tool for designing structures that can withstand intense ground motions. Its superior strength-to-weight ratio makes it an ideal material for creating flexible yet robust frames, which are essential for navigating the unpredictable forces of earthquakes. In industrial steel structure drafting, designers utilize this inherent property to develop intricate connections, ensuring that each component is securely interlocked, enhancing overall structural integrity.

When integrated into seismic design, steel’s ductility becomes a key advantage. Unlike rigid materials, steel can deform without failure, absorbing energy and allowing for controlled movement during an earthquake. This behavior significantly reduces the risk of collapse and minimizes damage to both the structure and its surroundings. With proper connection detailing, steel frames can resist lateral loads, enabling buildings to remain standing and safe during seismic events.

Drafting Connectors for Optimal Strength

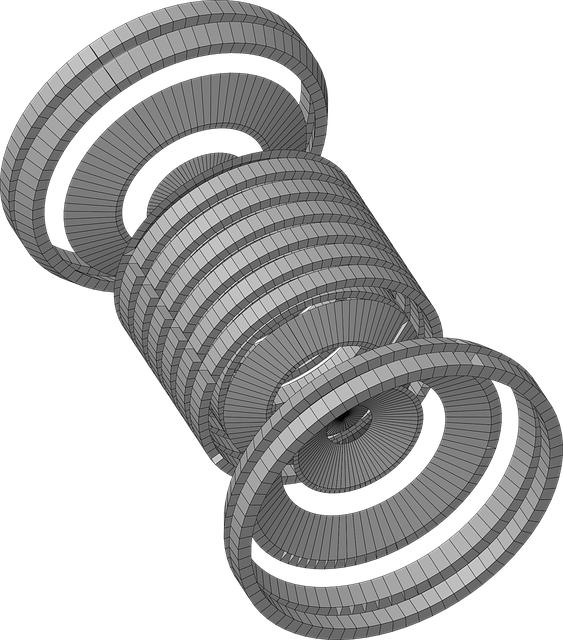

In the realm of industrial steel structure drafting, meticulous attention is paid to connectors to ensure optimal strength and seismic resistance. Drafting professionals meticulously design and specify connectors that align with stringent building codes and standards, crucial for structures facing potential earthquake activity. By leveraging advanced software and engineering principles, they create robust connections capable of withstanding significant forces, thereby enhancing the overall structural integrity.

Connectors are tailored to accommodate various load types, including tensile, compressive, and shear loads, which are prominent during seismic events. Properly drafted connectors integrate reinforcement elements like plates, angles, and bolts, strategically placed to maximize strength and minimize potential failure points. This meticulous approach ensures that the structure can withstand intense vibrations without compromising safety or structural integrity.

Key Details for Seamless Integration

Seamless integration of seismic-resistant features within industrial steel structure drafting is paramount for ensuring structural integrity during earthquakes. Key details include meticulous detailing of connections, utilizing specific fastening methods and materials resistant to seismic forces. Drafters must incorporate design elements like moment resistive frames, energy-absorbing devices, and flexible connections to mitigate the effects of ground motion.

Precision in industrial steel structure drafting is crucial for achieving these goals. Precise measurements, detailed drawings, and adherence to building codes are essential components. By prioritizing these aspects, drafters facilitate efficient construction, ensuring that the final structure not only meets but exceeds seismic resistance requirements, providing safety and stability in potentially hazardous environments.

Best Practices for Safe Structural Assembly

Creating a seismic-resistant structure requires meticulous planning and adherence to best practices, especially when using industrial steel. During the initial stages of design, incorporating specialized structural engineers with expertise in seismic engineering can ensure safety and compliance with local building codes. This collaborative approach should guide the entire process, from material selection to assembly methods.

In terms of industrial steel structure drafting, it’s crucial to focus on detailed connections. Seamless integration of components through welding or bolting requires precise calculations for load distribution. Regular inspections during construction verify the integrity of these connections, ensuring that each joint meets the required strength and stability standards. This meticulous attention to detail is what fosters robust structures capable of withstanding seismic activity.

Steel connection detailing plays a pivotal role in ensuring seismic-resistant structures. By understanding the unique properties of steel, drafting connectors for optimal strength, and adhering to best practices during assembly, engineers and architects can create robust and safe industrial steel structures. Seamless integration of these key details is essential for withstanding seismic events, making steel a preferred material for challenging environments. This comprehensive approach to structural design and construction guarantees the longevity and safety of steel-based projects.