Reinforcement detailing services leverage advanced software and precision technologies like CNC machines to create accurate steel component drawings and specifications. This ensures structural integrity, optimizes material use, saves time, enhances quality, addresses complex geometric challenges, and sets industry standards in fabrication and construction. Advanced digital tools integrated with meticulous human oversight guarantee reinforcement detailing meets or exceeds safety and performance standards.

In the realm of fabrication and construction, precision-driven steel detailing acts as the crucible where structural integrity meets meticulous craftsmanship. This article explores reinforcement detailing services, delving into how advanced technology enhances accuracy in fabrication while optimizing construction processes. From understanding the foundational role of steel detailing to implementing efficient strategies and ensuring quality assurance, each section unravels a vital aspect of this game-changer for modern construction.

Understanding Steel Detailing: Reinforcement's Foundation

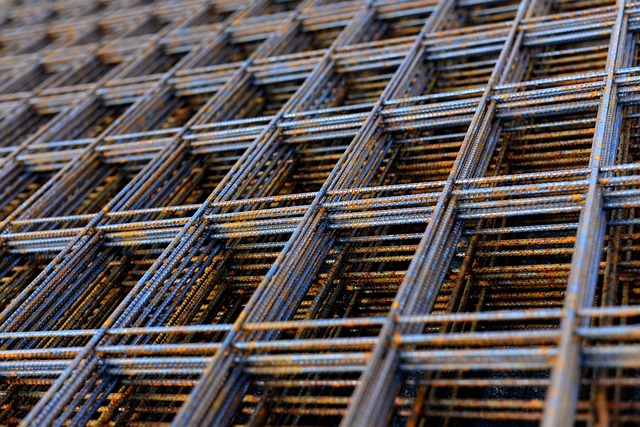

Steel detailing is a critical process that forms the backbone of any reinforcement structure in fabrication and construction projects. It involves meticulous planning and precise execution to ensure structural integrity and durability. At its core, steel detailing encompasses creating detailed drawings and specifications for various steel components, from beams and columns to connectors and brackets. These documents guide fabricators and builders, ensuring every element is crafted to the exact dimensions and requirements dictated by the project’s design.

By focusing on precision-driven steel detailing, reinforcement detailing services enhance overall construction quality. This approach involves utilizing advanced software tools to model and analyze complex steel frameworks, identifying potential issues early in the process. It also facilitates better material estimation, cost optimization, and efficient on-site assembly. Ultimately, precise detailing ensures that the final structure not only meets but exceeds industry standards for safety and performance.

Precision Technology: Enhancing Fabrication Accuracy

Precision technology has revolutionized steel fabrication, offering unprecedented accuracy and quality in construction projects. The integration of advanced machinery, such as CNC (Computer Numerical Control) machines, allows for intricate and precise steel detailing. This technology ensures every component is cut, formed, and assembled with meticulous care, reducing human error and enhancing overall fabrication precision.

For example, reinforcement detailing services benefit immensely from these advancements. Reinforcement bars, crucial for structural integrity, can be precisely cut and bent to fit complex architectural designs. This level of accuracy not only saves time but also ensures structural efficiency, resulting in stronger and more durable construction. The ability to achieve such fine detail has elevated the standards of steel fabrication across various industries.

Optimizing Construction: Efficient Detailing Strategies

In the realm of fabrication and construction, precision-driven steel detailing plays a pivotal role in optimizing the entire process. Efficient detailing strategies involve meticulous planning and execution to ensure structural integrity while streamlining workflow. By leveraging advanced technologies and specialized reinforcement detailing services, construction projects can achieve enhanced accuracy, reduced waste, and faster completion times.

These optimized detailing methods not only enhance the structural performance of steel elements but also contribute to overall project sustainability. With precise measurements and detailed designs, builders can navigate complex geometric challenges, ensuring seamless integration of steel components into the final structure. This, in turn, results in more robust and aesthetically pleasing constructions, setting new standards in the industry.

Quality Assurance: Ensuring Structural Integrity

In the realm of fabrication and construction, precision-driven steel detailing acts as a cornerstone for structural integrity. Quality Assurance (QA) processes are integral to this, meticulously scrutinizing every aspect of reinforcement detailing services. This includes checking dimensions, tolerances, and material specifications to guarantee that each component meets or exceeds industry standards. By implementing rigorous QA protocols, builders can mitigate risks associated with structural weaknesses, ensuring the safety and longevity of structures.

Moreover, advanced technologies play a pivotal role in enhancing QA. Digital tools enable accurate measurements, virtual simulations, and real-time data analysis, allowing for proactive identification and correction of potential issues before they escalate. This blend of meticulous human oversight and innovative technology ensures that every steel detail is not just correct but optimal, contributing to the overall structural soundness and beauty of constructed works.

In the realm of fabrication and construction, precision-driven steel detailing is not just a service—it’s a game changer. By leveraging advanced technology and implementing efficient strategies, industry professionals can significantly enhance structural integrity while streamlining project timelines. Optimizing reinforcement detailing becomes a powerful tool, ensuring that every component contributes to a robust, high-quality final product. For those seeking top-tier results, investing in precision detailing services is a strategic move that promises to revolutionize their construction projects.