Sheet metal design services leverage stress and load simulations using advanced software like FEA to ensure structural integrity and optimize performance of metal components. These tools allow engineers to predict component behavior under various real-world conditions, enhancing design quality and reducing failure risks. This methodology has revolutionized engineering, saving time, resources, and leading to higher product quality in industries such as automotive and aerospace through the development of lighter, stronger parts. By minimizing physical prototypes, sheet metal design services utilizing simulations enable faster product development cycles.

In the realm of manufacturing, sheet metal design plays a pivotal role across industries. However, validating these designs against stress and load constraints presents unique challenges. This article explores how stress and load simulations empower engineers in refining sheet metal design services. We delve into the complexities of sheet metal behavior, highlighting the critical importance of accurate simulations. Discover the process, tools, and benefits, including compelling case studies, that demonstrate why simulations are a game-changer for enhancing sheet metal design integrity and performance.

Understanding Sheet Metal Design and Its Challenges

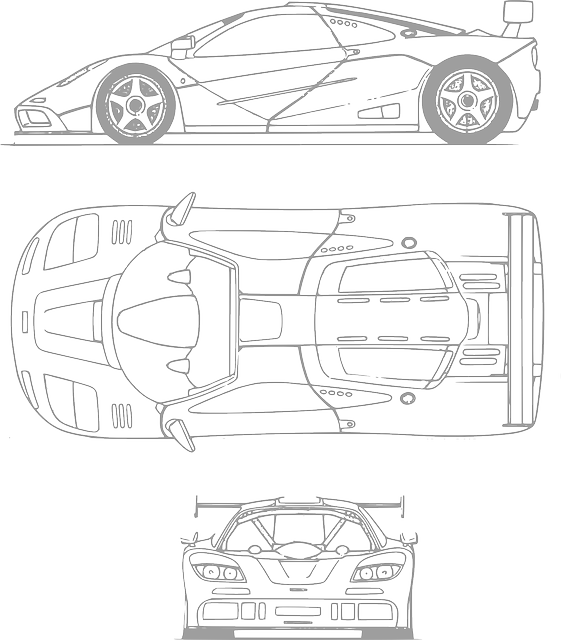

Sheet metal design is a specialized process that involves creating and shaping thin metal sheets into various forms and structures. It plays a critical role in numerous industries, from automotive manufacturing to aerospace engineering. The versatility of sheet metal allows for intricate and complex designs, enabling the creation of components essential for modern machinery and equipment. However, this very flexibility presents unique challenges during the design validation phase.

One of the primary hurdles is ensuring structural integrity while maintaining aesthetic appeal. Sheet metal parts must withstand specific stresses and loads without compromising their dimensional accuracy or visual quality. This requires a deep understanding of material properties, careful consideration of manufacturing processes, and advanced simulation tools. By employing stress and load simulations, engineers can predict and optimize performance, identifying potential weak points before actual production, thereby streamlining the design process for efficient and reliable sheet metal design services.

The Role of Stress and Load Simulations in Validation

In the realm of sheet metal design services, stress and load simulations play a pivotal role in validation processes. These simulations act as powerful tools that enable engineers to assess the structural integrity and performance of sheet metal components under various conditions. By subjecting digital models to realistic loads and stresses, designers can uncover potential weaknesses, identify areas of improvement, and ensure that the final product meets stringent safety and quality standards.

Load and stress simulations offer a comprehensive approach to validation by considering multiple variables, such as material properties, geometry, and boundary conditions. This detailed analysis allows for the prediction of deformation, strain, and stress distributions within the sheet metal structure. Through this data, designers can make informed decisions, optimize designs, and mitigate risks associated with structural failures or performance issues in real-world applications.

Process and Tools for Effective Simulation

In the realm of sheet metal design services, validation through stress and load simulations is a game-changer, ensuring the structural integrity of metal components. This process involves utilizing specialized software to replicate real-world conditions and predict how a sheet metal part will perform under various loads. By simulating these scenarios, designers can identify potential weaknesses or failures before production, thus saving time and resources.

Effective simulation requires access to powerful engineering tools capable of modeling complex geometry and applying precise load cases. Modern software packages offer advanced features such as finite element analysis (FEA), which divides the metal sheet into tiny elements to calculate stress distribution and deformation. This method enables engineers to refine designs, optimize material usage, and ensure compliance with industry standards and safety regulations.

Benefits and Case Studies of Implementing Simulation in Sheet Metal Design Services

Implementing simulation technologies in sheet metal design services has revolutionized the way engineers and designers approach structural integrity and performance optimization. One of the primary benefits is the ability to conduct thorough stress and load simulations, allowing for precise predictions of how a metal component or assembly will behave under various conditions. This proactive approach to design validation significantly reduces the risk of failures or defects in final products, leading to cost savings and enhanced product quality.

Numerous case studies demonstrate the success of integrating simulation into sheet metal design services. For instance, in automotive manufacturing, simulations have been instrumental in designing lighter yet stronger body panels, contributing to improved fuel efficiency and vehicle safety. Similarly, aerospace companies have leveraged these tools to optimize the structural integrity of aircraft components, ensuring they meet stringent weight and performance standards. By minimizing physical prototypes and iterative testing, simulation streamlines the design process, enabling faster time-to-market for innovative sheet metal products across diverse industries.

Sheet metal design, a critical component in various industries, benefits immensely from stress and load simulations. These advanced tools enable designers to validate structures, predict performance under real-world loads, and optimize designs efficiently. By integrating simulation into sheet metal design services, professionals can streamline processes, reduce errors, and deliver more robust, reliable products. This approach has proven successful across multiple case studies, highlighting the significance of embracing technology for enhanced quality and productivity in sheet metal manufacturing.