Precision industrial metal detailing is an art that transforms raw structural metal into custom functional metalworks through advanced craftsmanship and fabrication techniques. Skilled metalworkers bring technical drawings to life, creating intricate parts for diverse industries like automotive, aerospace, construction, and medical devices. This process involves meticulous planning, advanced machinery, and tight tolerances, ensuring superior performance and reliability in both functional metalwork and heavy metal fabrication. Industrial designers play a crucial role in balancing form and function, resulting in durable, safe, and aesthetically pleasing solutions that enhance industrial settings.

Precision Industrial Metal Detailing: Unlocking Innovation and Functionality

In today’s demanding industrial landscape, precision metal detailing is no longer an option—it’s a necessity. From aerospace to automotive and beyond, functional metalwork underpins cutting-edge innovations. This article explores the intricate world of heavy metal fabrication, delving into its defining characteristics, essential techniques, and the transformative role of custom metalwork in industrial design. We’ll uncover best practices for ensuring quality and longevity, highlighting the paramount importance of precision industrial metal detailing across various sectors.

- Understanding Precision Industrial Metal Detailing

- – Definition and importance in various industries

- – Key aspects of high-quality metal detailing

- Materials and Techniques Used in Heavy Metal Fabrication

Understanding Precision Industrial Metal Detailing

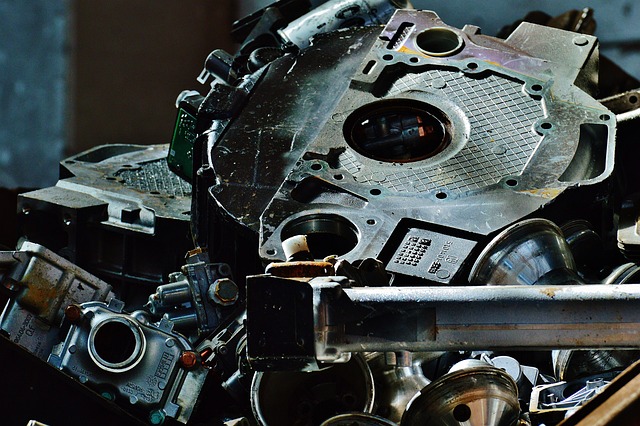

Precision industrial metal detailing is an art that combines meticulous craftsmanship with advanced fabrication techniques to create intricate and functional metalworks. This specialized field focuses on transforming raw structural metal into custom designs, ensuring every element serves a specific purpose in various industrial applications. From heavy metal fabrication to utility metalwork, the process demands an unparalleled level of accuracy and attention to detail.

Industrial metalworkers skilled in this domain bring concepts to life by translating technical drawings and specifications into tangible, high-quality pieces. They meticulously plan each stage, from initial design consultation to final assembly, utilizing advanced machinery and tools to achieve flawless results. Whether it’s a custom industrial part or an entire structural framework, precision metal detailing plays a vital role in enhancing the functionality, durability, and aesthetics of modern machines and structures.

– Definition and importance in various industries

Precision industrial metal detailing is a specialized art that involves creating intricate and exacting designs from various types of metal. This meticulous process encompasses everything from heavy metal fabrication to functional metalwork, ensuring structural integrity while achieving exceptional aesthetic appeal. It plays a pivotal role across diverse industries, ranging from automotive and aerospace to construction and medical devices.

In these sectors, custom metalwork is often required to meet specific functional needs or adhere to stringent design specifications. Whether it’s crafting intricate components for machinery, forming structural elements for buildings, or designing medical equipment, precision metal detailing ensures superior performance and reliability. The meticulous nature of this work demands a deep understanding of materials, advanced fabrication techniques, and adherence to tight tolerances, ultimately contributing to the success and innovation within each industry.

– Key aspects of high-quality metal detailing

High-quality metal detailing in industrial applications is a harmonious blend of art and engineering, where precision meets functionality. Key aspects include meticulous craftsmanship, adherence to strict tolerances, and consideration of both aesthetic and structural integrity. Each piece, whether part of intricate machinery or robust structural metalwork, demands meticulous attention to detail, from initial design through final assembly. This process involves advanced techniques in heavy metal fabrication, ensuring every curve, corner, and joint meets the highest standards of accuracy and strength.

Industrial designers play a pivotal role in bringing custom metal creations to life, balancing form with function. The beauty of functional metalwork lies not only in its visual appeal but also in its reliability under extreme conditions. Whether it’s utility metalwork for industrial settings or heavy metal fabrication for specialized equipment, the goal is always to deliver durable, safe, and efficient solutions. This meticulous approach ensures that every project, from start to finish, reflects a commitment to excellence in both the craft and the industry.

Materials and Techniques Used in Heavy Metal Fabrication

In the realm of heavy metal fabrication, a myriad of materials and techniques come together to create robust and durable structural metal components that underpin countless industrial applications. The process often involves custom metal fabrication, where skilled artisans transform raw sheets of industrial metal into intricate designs tailored to specific project requirements. This art is particularly crucial in the domain of functional metalwork, ensuring each piece not only serves its intended purpose but also meets stringent quality standards.

Techniques range from straightforward cutting and bending to more complex processes such as laser cutting and CNC machining. The latter enables precise engineering and intricate detailing, making it ideal for creating complex geometric shapes or fine textures. This level of craftsmanship is evident in the production of utility metalwork, where structural metal components are designed not just for strength but also for aesthetic appeal, seamlessly integrating into modern industrial design trends.

Precision industrial metal detailing is a cornerstone of modern manufacturing and essential for creating durable, aesthetically pleasing, and highly functional components across various industries. From intricate machine parts to robust structural metal, high-quality metal fabrication ensures the reliability and longevity of products. By leveraging advanced materials and techniques, including custom metalwork tailored to specific design needs, industrial metal artisans contribute significantly to the development of both everyday items and complex machinery. Whether for utility metalwork or artistic industrial design, precision detailing remains a game-changer in enhancing the performance and visual appeal of functional metal pieces.